|

Solving the Banding

Problem |

| |

|

The main causes of banding are:

|

| |

|

-Printhead problems.

-Use of Non-HP media.

-Incorrect media type selected in the front panel.

-Media advance problems. |

| |

Banding Caused by Printhead

Problems

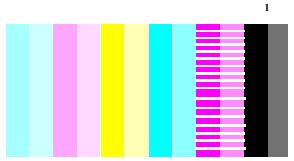

Banding caused by problems with the Printhead(s) will be highlighted

in the Diagnostic Print because the banding is not in all of the

colors, the colored strip that has banding was caused by the same

colored Printhead.

In the following example, there is a problem in the Magenta Printhead.

There will be clear repetitive bands (perhaps white) in the magenta

column.

|

|

|

| |

|

|

1. Perform Printhead

Recovery (See How to fix the Nozzle

Defects).

2. If there is no improvement after Printhead

Recovery, replace the failing Printhead. |

| |

Banding Caused by Media

Advance Problems

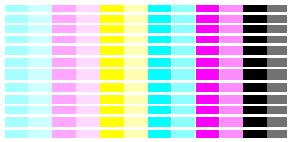

Another type of banding is caused by an inaccurate media advance.

In this case there will be banding (horizontal repetitive bands

along the test pattern) in all the color columns.

The bands can appear as dark bands, due to a shorter advance of

the roller which causes an overlap, or lighter bands due to a longer

advance causing spaces.

Banding in all of the colors

|

| |

|

| |

|

|

1. If the image

is grainy, this could also be a symptom of problems with the bidirectional

alignment (See Solving Bidirectional

Alignment Problems). If the Bidirectional Alignment

pattern has no problems go to step two.

2. Make sure that the media selection made in

the front panel is the same as the media that you have loaded.

3. It is possible that the banding was caused

because the customer was using non-HP media. If the customer still

wants to use non-HP media, recalibrate the paper accuracy by performing

the User's Accuracy calibration and NOT the Service

Accuracy Calibration (Refer to the User's Guide). Performing this

will overwrite the default setting for only the

paper that you have selected.

4.Perform the Printheads alignment procedure (Refer

to the User's Guide). |

|